Take The Complexity Out Of IIoT And IoT

The purposes of IoT include collecting application or machine data, connecting various devices, and getting real-time custom alerts/notifications - all of which can improve your business operations and give your company a sustainable advantage. However, creating an IoT solution can be complex. Setting up an IoT network includes:

- Connecting devices from different manufacturers, each of which has its own functions, interfaces and protocols.

- Capturing and reconfiguring data in a secure and cost-effective way.

- Delivering this data to enterprise systems for business intelligence (BI).

- Displaying BI insights on dashboards and apps.

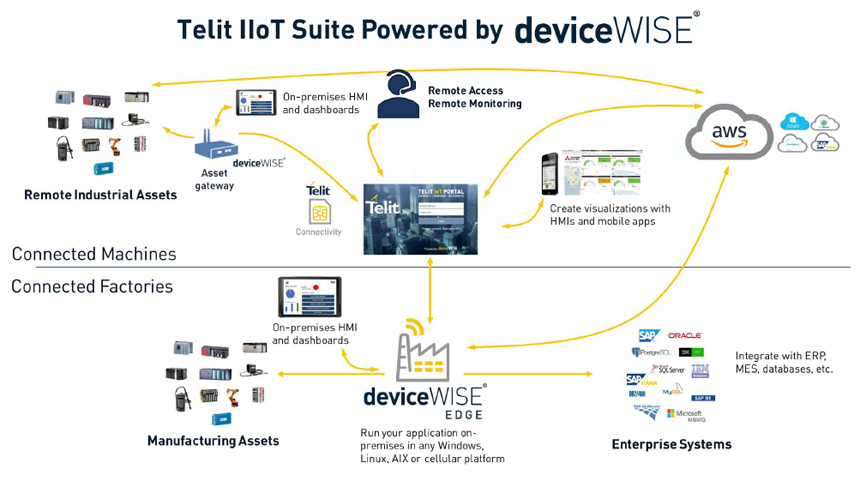

Telit products can help you develop a reliable end-to-end IoT solution. Telit has:

- A broad portfolio of specialty IoT communication modules with advanced technologies for demanding environments.

- Connectivity tools for deploying devices under cellular networks.

- A comprehensive IoT platform software to run critical functions and collect, manage and connect device data for the cloud and analytical systems.

Make Your Process Industry 4.0 Ready

TAKE CORRECTIVE ACTION BEFORE ISSUES OCCUR.

With conditional monitoring IoT solutions, manufacturers can prevent damage and reduce maintenance costs by utilizing process information gathered in real-time:

- Sensors track changes in vibration, temperature and output to detect any issues with corrosion, wear, misalignment, imbalance or lubrication.

- Service maintenance can automatically be scheduled ahead of time to prevent part failure or system damage.

- Critical outages and unplanned downtime can be avoided by identifying potential equipment failure.

IMPROVE OPERATIONAL VISIBILITY.

The IIoT is revolutionizing manufacturing. Connecting assets throughout the industrial value chain provide complete operational visibility to allow for real-time decision-making and improved levels of quality and efficiency as well as new service opportunities. With Telit’s smart manufacturing/Industrial IoT solutions, you can connect any manufacturing asset to any enterprise system vertically and horizontally without programming.

DETECT OPPORTUNITIES FOR IMPROVEMENT.

IoT-enabled condition monitoring solutions give manufacturers the data they need to make smarter decisions about operations. By identifying areas for improvement, manufacturers can boost productivity and efficiency while reducing operational costs:

- Monitor and analyze machine performance to implement necessary upgrades or enhancements.

- Prevent the need for costly truck rolls by sending the right supplies when needed.

- Eliminate the need for excessive inventory of spare parts to reduce downtime.

PREVENT UNPLANNED DOWNTIME.

After outfitting machines with sensors to monitor abnormalities that can be early indicators for servicing (e.g. temperature changes, vibration, etc.), manufacturers can analyze data to:

- Maximize equipment uptime by predicting equipment malfunctions before they happen and schedule maintenance ahead of time.

- Optimize resource management by sending technicians with the right parts at the right time.

- Improve product quality and reliability to enhance customer satisfaction.